Product Certification

- 2006/42/EC Machine Safety Regulation

- 2014/35/EU LVD (Low Voltage) Regulation

- 2014/30/EU EMC (Electromagnetic Compatibility) Regulation

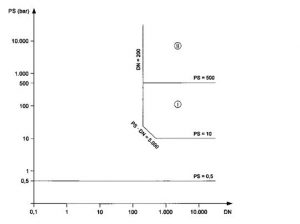

- 2014/68/EU PED (Pressure Equipments) Regulation

- 2014/33/EU Lift Regulation

- G Certificate

- Atex Certificate

- Gost R Certificate

- Ukrayna Ukr SEPRO Certificate

- Helal Certificate

- EAC Certificate

2014/30/EU EMC (Electromagnetic Compatibility) Regulation

The EMC Directive defines electromagnetic compatibility as “the ability to operate satisfactorily, without causing electromagnetic interference, which may be irritating to other devices or facilities present in the vicinity of an equipment or facility in an electromagnetic environment”. The machine and components must be selected and verified to withstand any potential interference. Higher requirements apply for safety devices. Electromagnetic interference may occur because of below stated:

Fast transient electrical interference (Burst)

Pulse voltage (surge), for example stroke of lightning the network.

Electromagnetic fields

High frequency interference (from neighboring lines)

ElectroStatic discharge (ESD)

All electrical and electronic equipment or installations interact with each other, when they are connected or be nearby. For example, television or radio is interfering with when due to the nearby refrigerator or the power line passing above. The EMC conditions are designed to keep these side effects under control at a reasonable level. Similarly, many units in cars are electronically managed and any interaction can lead to incorrect operation. Therefore, important to evaluate these systems by the EMC regulations for quality and functional safety.

EMC standards serve two purposes internationally:

*They regulate the electromagnetic emission from a device.

*They ensure the immunity of the device to electromagnetic interference.

The ECP supports to customers about the documentation, the test report and the technical file according to EMC compliance. Join the ECP family for fast and reliable certification process.

2014/33/EU Lift Regulation

CE marking is a legal requirement for companies which manufacture or install elevators. The elevator companies which providing installation, maintenance and revision services are obliged to prepare technical files according to relevant regulations and standards. Obliged to implement the ISO 9001: 2015 Quality Management System at the operations and to certify compliance with the 2014/33 / EU Elevator Regulations of the electric or hydraulic elevator assembly / manufacture / revision have maded to the Notified Body. Can marked CE on the assembly / manufacture / revision of the elevator after the approval of the Notified Body.

Companies of elevator which the manufacture, install or revision should consider the 2014/33 / EU elevator regulations (eg 95/16 / EC). Electrical and hydraulic elevator installation, maintenance and revision should be according to TS EN 81-20 (ex: TS EN 81-1 + A3, TS EN 81-2 + A3) harmonize standard to ensure full compliance.

The Elevator Directive specifies the basic health and safety requirements that must be fulfill before supply to the market for elevators and their associated elevator safety components used to transport people, people and loads or just loads.

Creation of Elevator Technical File according to CE Criteria

The companies of which are manufacture and installation of elevator or manufacture of safety components of elevator, are responsible for preparing the technical file for their products. A copy of the technical file which is prepared by the manufacturer, should be at company and other copy should be at Notified Body (if certificated); also one of the other copy should be ready to give when requested by the competent authorities, importer or authorized representative located at that country.

Documents, test reports and other documents submitted in the European Union New Approach Directives should be included in the technical file content.

The recommended documents to be included in the technical file content are below stated:

The general description of the elevator model

Drawings of design and manufacturing, calculations and diagrams

Considered directives and harmonized standards and instruments that are agreed to provide them

A copy of the EU Declarations of Conformity of the safety components used in the manufacture of elevators

Made or get done the results of each experiment and calculations by the manufacturer

A copy of the lift’s handbook

Measures taken at the manufacturing stage to ensure that the manufactured elevators or elevator safety components comply with the legal provisions of this Directive.

Creation of EU Declaration of Conformity

The EU declaration of conformity is a declaration that the manufacturer of the elevator or the manufacturer of the elevator safety components has manufactured the product according to the requirements of the Elevator Directive. The EU declaration of conformity is issued and declared by the manufacturer of the elevator safety components or the elevator.

The content of the EU declaration of conformity, which shall be established for elevators by elevator assemblers, below stated:

The name and address of the company which performed the assembly of the elevator,

The description, the type or serial details and the serial number of the elevator and the address where the elevator is assembled,

Assembly year of the elevator,

All relevant provisions about elevator,

Reference to harmonized standards ascribing,

The name, address and identification number of the notified body which performs the EU type examination of the elevator model,

Ascribing EU type examination document,

The name, address and identification number of the notified body that verifies the elevator,

The name, address and identity number of the notified body which audit the last inspection of the elevator,

The name, address and identification number of the Notified Body which audit the Final Inspection,

The identity of the signature authorized to act on behalf of the elevator assembly,

For elevator safety components, the content of the EU declaration of conformity, which shall be established by the manufacturer:

Name and address of the manufacturer of the safety components,

The description of the safety feature, type or serial details, serial number if any; if can’t be understood, in the safety function of the safety components,

The date of manufacture of the safety components,

All relevant provisions of the safety components,

Reference to harmonized standards ascribing,

The name, address and identity number of the notified body which performs the EU type examination,

Ascribing to the EU type examination document issued by the Notified Body,

The name, address and identity number of the Notified Body which performs the manufacturing inspections,

The name and address of the notified body which controls the quality assurance system.

After all these operations, the CE conformity mark can be affixed to the product. The CE conformity marking must be on the safety components, if it is not possible, must be on the packing on the elevator safety components. At this stage, the elevator or elevator safety component, which has the technical document prepared, the declaration of EU conformity and the CE conformity mark attached, has been supplied to the market according to the Elevator Directive (2014/33 / EU).

How should CE Marking be affixed at elevators?

At the elevators whose assembly is completed, beside the CE conformity mark;

The identification number of the notified body performing the final inspection of the B + F module,

The notified body identification number, which performs product quality assurance inspection of the B + E module,

The notified body identification number, which performs manufacturing quality assurance inspection of the B + D module,

The notified body identification number which perform inspection of the G module,

Mandatory to be the notified body identification number, which inspection the full quality assurance at the H module.

How Should CE Marking be Affixed to Safety Components?

Beside the CE conformity mark of the elevator safety components;

At the modification of the B + C modules, the manufacturer of the safety components will attach the CE conformity marking to each safety components,

At the modification of the B + E modules, the identification number of the notified body, which performs the product quality assurance inspection together with the CE conformity mark,

At the H module, it is mandatory to be the notified body identification number, which performs full quality assurance inspection with the CE conformity mark.